These diffs fail for a couple of reasons:

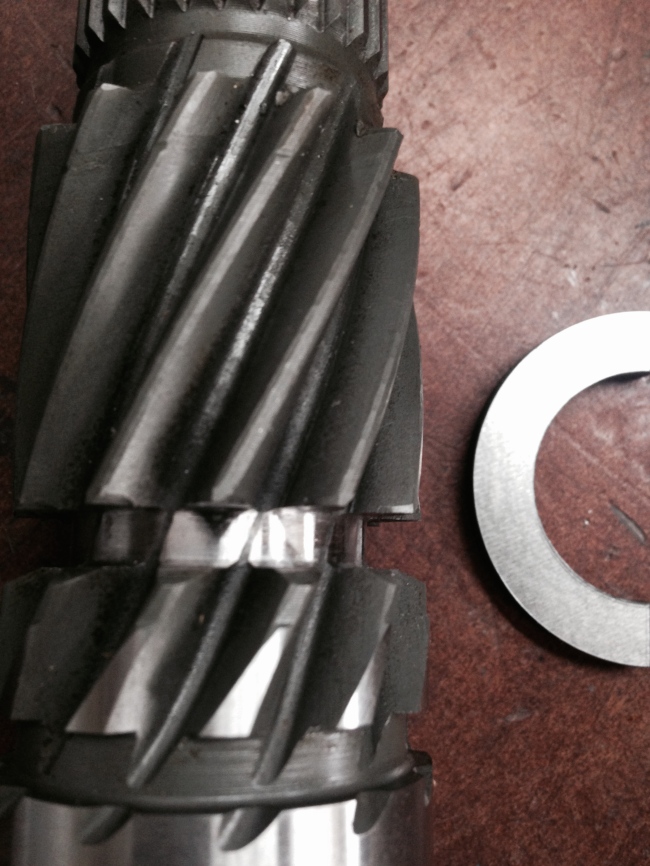

- small pinion gear

- cast iron bearing caps snap under heavy torque loads

- pinion crush tube collapses, leading to no bearing preload

- driver abuse

We address the issue of the small pinion gear by strengthening it with shot peening and ISF/REM treatment (Complete rebuild only).

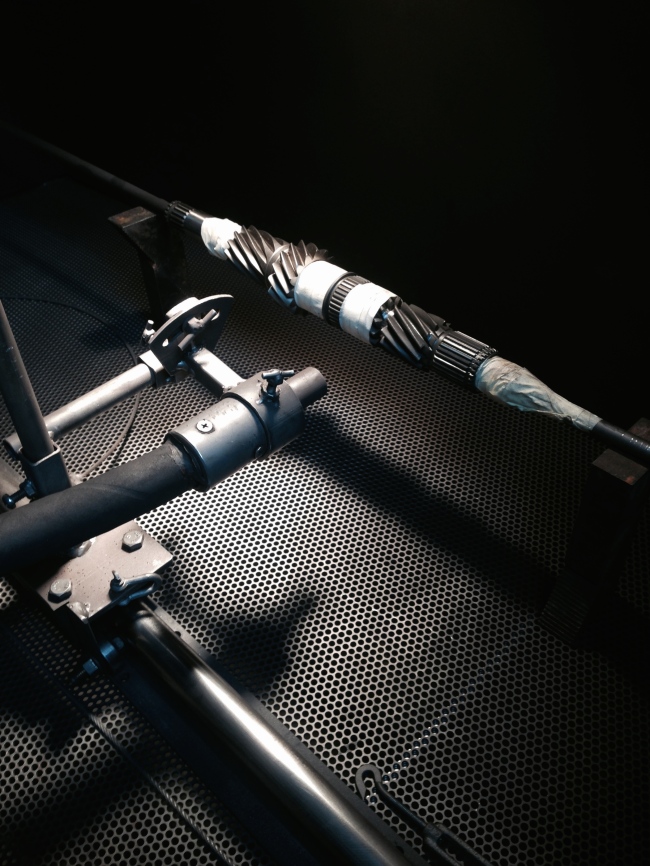

The CT Engineering billet bearing caps stop bearing cap flex and misalignment, and prevent the cast caps from braking.

The solid collar replacement by J’s Racing prevents pinion bearing failure (Complete rebuild only).

Nothing can prevent driver abuse except the driver. While these diffs will be extremely reliable, they will still break if you clutch dump at high RPM with sticky tyres and/or a turbo. Just like any other diff on the planet.

Rebuild Options we offer:

Basic: $1,750

Includes all of the following:

basic rebuild kit (genuine Honda):

- pinion bearings

- crush tube

- pinion seal

- axle seals

- pinion nut

- pinion shim

CT Engineering billet caps (custom machined to housing)

Shot peen original cast iron bearing caps

ARP fasteners

Chemical clean components

Thermal dispersant coating on housing to help the diff shed heat

Meticulous assembly in dedicated clean room

- set backlash

- set mesh pattern

- set bearing preloads

- all fasteners to factory torque values

Complete: $2,500

This is as close to bulletproof as an S2000 diff will get.

Includes all of the following:

complete rebuild kit (genuine Honda/J’s Racing):

- pinion bearings

- carrier bearings

- J’s Racing solid pinion collar

- pinion seal

- axle seals

- pinion nut

- pinion shim

- crownwheel bolts

- Dimple magnetic drain plug

CT Engineering billet caps (custom machined to housing)

Shot peen original cast iron bearing caps

ARP fasteners

Chemical clean components

Hot tank gear set^

Crack test gear set^

Demagnetise gear set^

Shot peen gear set

ISF/REM treat gear set

Thermal dispersant coating on housing to help the diff shed heat

Meticulous assembly in dedicated clean room

- set backlash

- set mesh pattern

- set bearing preloads including J’s collar setup and shimming

- dial in LSD and crown wheel to reduce any runout

- all fasteners to factory torque values

Add new gear set:

Can be applied to either the basic or compete packages. 2 Ratios available (more on request):

4.77:1 $550

4.44:1 $880

These are “genuine” gears, made by Mazda – the same supplier as Spoon and J’s Racing.

We can build your diff with your choice of LSD from reputable companies such as Kaaz and Spoon, too, if you want a more aggressive clutch type engagement.

If your housing or bearing caps are already cracked or broken this will cover the outright cost of a new housing.

You still need to send your diff, even if it’s cracked, so we can use the other components such as the front flange, side screws, rear cover, LSD centre etc. in your rebuild.

The price of the rebuild does not include replacement gears: if you supply a good set of gears we will use those. If yours are broken you need to either purchase a new set, or we may have second hand sets in stock which you can purchase.

^We only prepare used gears in this fashion – it is not required for new gear sets.

Finally, we have a real solution to this problem.

Finally, we have a real solution to this problem.